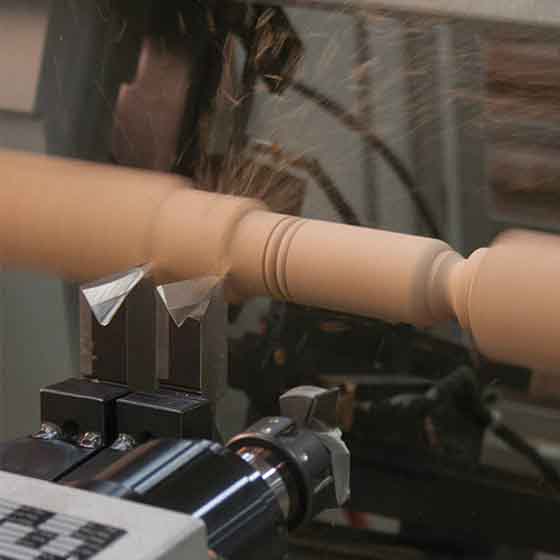

Amana Tool High Speed Steel (HSS) Carving CNC 2D and 3D ZrN Coated Router Bits

Option

Amana Tool High Speed Steel (HSS) Carving CNC 2D and 3D ZrN Coated Router Bits

HSS1300 - 6.2 Deg Tapered Angle Ball Tip x 1/32 Dia x 1/64 Radius x 1 x 1/4 Shank x 3 Inch Long x 3 Flute Up-Cut Spiral

JMP Wood Linden

621 Commerce Road

Linden NJ 07036

United States

Tools are manufactured with high balance that allows them to run up to 60,000 RPMs. Adjust your chip load and feed rate accordingly.

Applications:

- A perfect bit for 3D carving

- Precision 2D and 3D large scale carving

- Great for deep profiling

- Dimensional signage

- 3D millwork

- 2D and 3D contouring, profiling, modeling and pattern making for cabinetry, sign making, furniture making and jewelry mold making

- Perfect for model-makers on large 3D milling profiles in abrasive EPS foam and other materials

Excellent for cutting:

- Acrylonitrile-Butadiene-Styrene (ABS)

- Acrylic

- Acrylic Stone

- Aluminum

- Brass

- Bronze

- Composite

- Copper

- Corian

- Coroplast®*

- Dibond®

- Ethafoam***

- Ethylene-vinyl Acetate Foam (EVA)

- Expanded Polypropylene (EPP)**

- Expanded Polystyrene Foam (EPS)

- Extruded Polystyrene Foam (XPS)

- Fiberglass

- Fiberglass PCB Board

- Foam Board

- Graphite

- High Density Polyethylene (HDPE)

- High Density Urethane (HDU)

- 20lbs High Density Urethane

- Lexan™

- MDF/HDF

- Non-Ferrous Metals

- PALFOAM™

- Phenolics

- Phenolic Composites

- Plastics

- Poly (methyl methacrylate) (PMMA)

- Polyethylene Foam***

- Polylam***

- Polyurethane Foam

- PVC

- PVC Foam Board

- Sign Board

- Sign Foam

- Titanium

- Tooling Board

- Wood

- XPE (Cross Linked Polyethylene) Foam

*A soft plastic cardboard made with super soft, super flexible PVC.

**Expanded polypropylene (EPP) is a foam form of polypropylene.

***Ethafoam, Polyethylene, and Polylam are durable, flexible, closed-cell foams with excellent memory.

Benefits of Zirconium Nitride (ZrN) Coating

- Creates a harder and tougher cutting edge allows for a prolonged cutting edge life and helps to prevent the build-up of material in the flutes while cutting

- Have the tendency to run/spin much faster than an uncoated tool

- Optimized flute geometry and low Total Indicated Runout (TIR) guarantees clean cuts, essentially eliminates sanding and reduces chatter (where the machine or work piece vibrates) under high chip loads (when used with low TIR spindles)

- High flute volume supports high feed rates and chip loads

- High aspect ratio for single pass deep-reach cutting

- Flute geometry optimized for cutting sign foam, sign board, hardwoods, thermoplastics and phenolic composites

Milling Plastics:

In a milling application, all plastics tend to behave differently so attention must be paid first and foremost to heat input, as that greatly impacts surface finish and chip control.