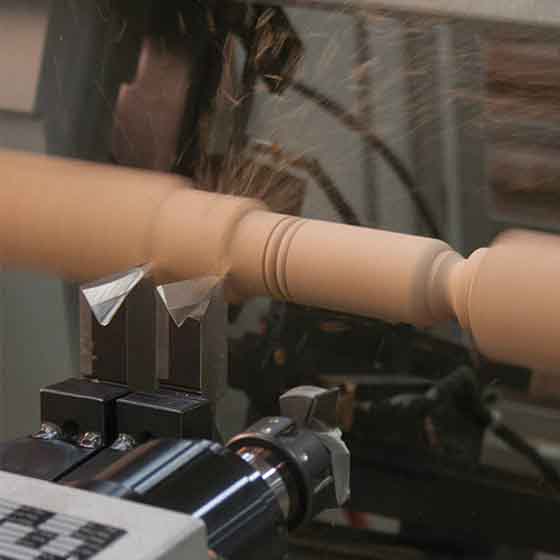

Amana Tool Solid Carbide 'O' Flute Spiral Ball Nose Aluminum Cutting

Option

Amana Tool Solid Carbide 'O' Flute Spiral Ball Nose Aluminum Cutting

51876-Z - Up-Cut, Aluminum Cutting 1/16 R x 1/8 Dia x 1/2 x 1/4 Shank ZrN Coated

JMP Wood Linden

621 Commerce Road

Linden NJ 07036

United States

Using the highest quality sub-micrograin carbide these bits have a special proprietary edge processing system featuring a super high polished cutting edge with a unique “mirror finish” resulting in clean cuts, less chance for chip re-welding, a superior surface finish and a longer tool life.

Specifically designed for a variety CNC machining applications excellent for cutting:

- ALPOLIC® Copper Composite

Material (CCM) - Alucobond®

- Aluminum

- Aluminum 5052

- Aluminum 6061

- Aluminum Alloys

- Aluminum Composite

Materials (ACM) - Aluminum Composite Panel (ACP)*

- Alupanel®

- Brass

- Copper

- Dibond®

- Durabond**

- e-panel™

- Etalbond®

- Fomex® with Aluminum Face

- Gold

- Non-Ferrous Metals

- Plastic

- Silver

- Solid Surface

- Titanium Composite Material (TCM)

- Wood

Ideal for industrial applications our spiral ‘O’ flute router bits are manufactured using innovative techniques and materials that yield superior results with each cut and help make aluminum projects less labor-intensive.

- Razor sharp cutting edge

- Effortless chip removal

- Helps prevent chip re-welding

- Extends tool life

- Exceptional cut quality

- Dissipates heat well and prevents melting

*Aluminum composite panel (ACP) is a type of ACM flat panel that consists of two thin aluminum sheets bonded to a non-aluminum core. ACPs are frequently used for building facades external cladding insulation and signage. **Durabond is a polyethylene core with 0.3mm colored aluminum sheet on either side pre-finished requiring no decoration.

Benefits of Zirconium Nitride (ZrN) Coating

- Creates a harder and tougher cutting edge allows for a prolonged cutting edge life and helps to prevent the build-up of material in the flutes while cutting

- Have the tendency to run/spin much faster than an uncoated tool

- Optimized flute geometry and low Total Indicated Runout (TIR) guarantees clean cuts, essentially eliminates sanding and reduces chatter (where the machine or work piece vibrates) under high chip loads (when used with low TIR spindles)

- High flute volume supports high feed rates and chip loads

- High aspect ratio for single pass deep-reach cutting

Warning: Never attempt to cut ferrous metals with these bits.

Inspect cut quality adjust feed / speed accordingly.

For optimal results and extended tool life use mist lubricant system or air cooling.

Maximum RPM: 35,000.